Did you know anything about the double disc check valves? These custom parts are used widely in numerous everyday devices and machines. So, in this article I will cover all the thing related to dual disc check valves like what is excelisdual disc Check Valve where we can use them which one should you choose and how to maintain it properly. Make sure you read untill the end and learn this Key Components!

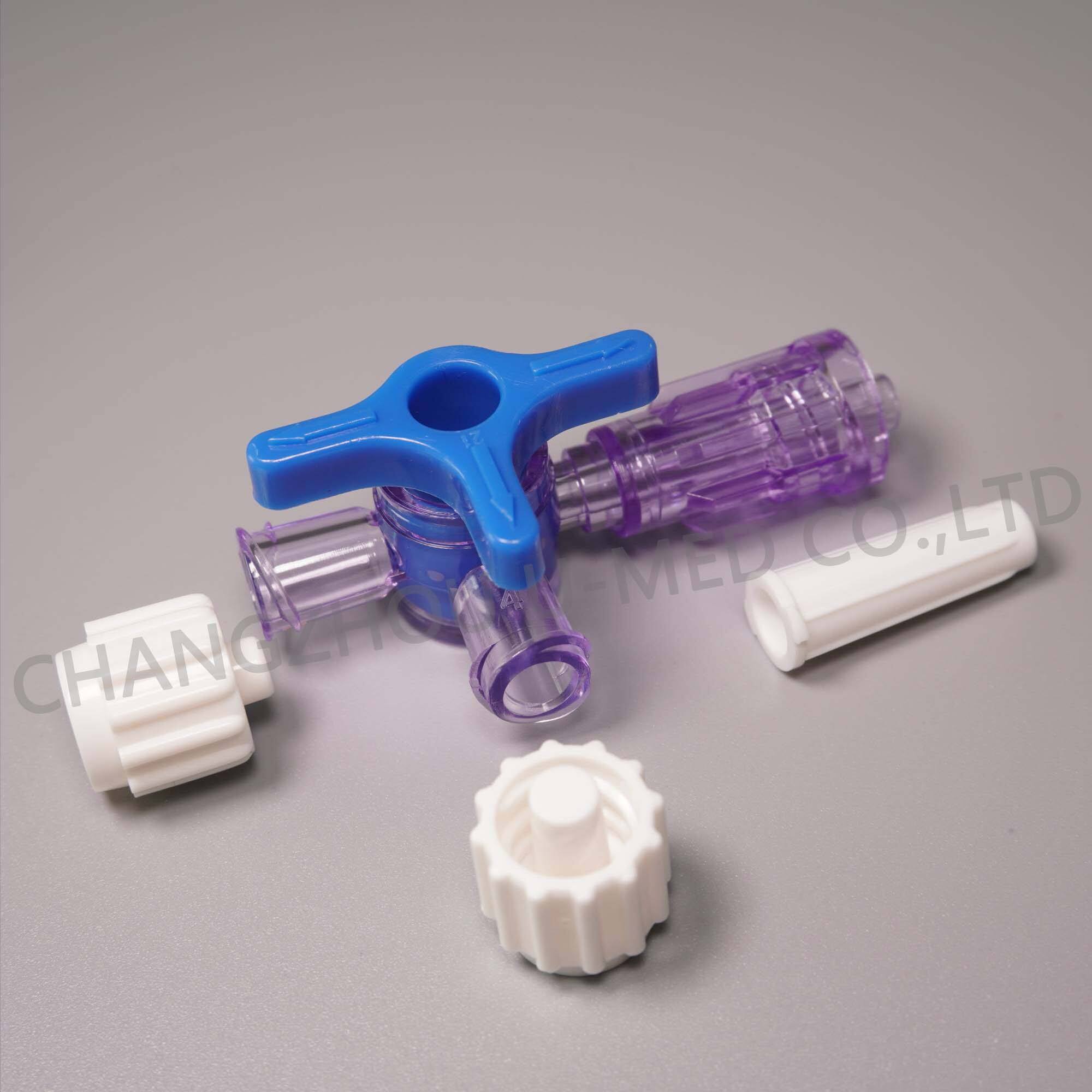

DUAL DISC CHECK VALVE Dual Disc Check Valve is known as one of the special devices that control how fluid (liquid or gas) enter each portion in a system. They permit one-way flow of a liquid or gas but do not allow it to move in the opposite direction. That is critically important because it keeps gas or liquid from flowing backwards. Two flaps or disks opening and closing as required. This is what makes them “dual disc” because they use 2 items working with each other to regulate the circulation.

There are a variety of circumstances where dual disc check valves can be extremely useful The trick about them is, they help create a near air-tight seal. In the closed state of this valve, no liquid or gas can therefore escape. Leaking can cause machines to stop working and expensive repairs. Dual Disc Check Valve, designed to control leakage and keep machinery operating properly They are also pretty durable and will last a while even in hot environments or under high pressure. Durability is a very good benefit and for this reason, they are considered to be one of the best rubber gloves that can use in many places.

There are a number of machines and places where you can find the dual disc check valves. Perforated wells are usually found in pipelines (which sends liquids and gases), In addition, they are used in the pumps, which work for pumping these fluids and turbines that give just single injection power. In addition to these most common applications, dual disc check valves are also used in other industries including oil & gas and chemical manufacturing — basically anywhere power generation takes place. They are intended to prevent backflow, but work differently in all these set ups as liquid or gas may be trying to flow backwards. The backflow can create problems and malfunctions in machines, because of this dual disc check valves are very important for safety and efficiency.

There are a few key things addition to consider when you have to choose the dual disc check valve. The size of valve depends on its application whether it will be suitable within the diameter if pipe or machine in which you have fitted. Another thing you would want to make sure of, it if the valve is too big or small for your compressor that will not work as planned either. Then you should think over the valve material. There is additional complexity because the liquid or gas that will come into contact with yourpackage must be considered when choosing material. Since some materials can react very differently to various fluids, gases and chemicals, it is important that you take into account the items which must be cleaned with a steam cleaner in order for them not to get damaged by using this great product.

Also think about the operation of the machine. If this machine is used in high-pressure or high-temperature situations, you will need a valve designed to be able to handle those conditions. Furthermore, some valves are designed for flow in one direction while others can only be used with a bi-directional flow. That being said, the knowledge of these differences will help you cater to that fact in making your purchase decision.

For maintaining the performance of your dual disc check valves, you need to manage them properly. This would include the cleaning of the valve to remove any dirt or rubbish that can accumulate in it over time. Checking for leaks and testing the valve to ensure it is operating correctly may also be wise. Being in working condition and avoiding possible problems regular check-up inspections are needed for the valve.

our dedicated after-sales service team is dedicated to quickly addressing and resolving any problems customers may encounter during product use this proactive approach helps ensure customers have a pleasant and dual disc check valves experience further demonstrating our commitment to customer satisfaction and fostering long-term trust

dual disc check valves provides a variety of products that are designed to meet the varied needs of the medical field. They offer top-quality and durable products across the board.

Changzhou U-med Co., Ltd founded in 1999 has dual disc check valves its name as a major manufacturer of OEM disposable medical consumable plastic and rubber parts. Our business, based in Changzhou City (Jiangsu Province) is equipped with modern production techniques, and 100,000-level assembly workshops to ensure the highest quality of our products. The state-of-the-art equipment for visual inspection and compliance with ISO13485 standards underscore our commitment to excellence. Our sophisticated production facilities, along with our flexible and efficient structure for our organization allows us to adjust quickly to changes in the market and make informed, quick decision-making. We are honored to have been recognized by many world-class clients and consider ourselves to be a model of rapid and healthy growth within the field. Our comprehensive after-sales program increases customer trust by solving any issues that might occur during the use of the product.

dual disc check valves range products designed satisfy variety medical requirements products result advanced technology unique manufacturing procedure offer outstand performance offer reasonable prices make sure clients access top-quality medical equipment compromise affordability dedication quality reflected every product offer ensure meet various customer demands precision